Why Choose Us ?

Customized services

We understand that each customer has unique manufacturing needs. That's why we offer customization options, to cater to your specific requirements.

Advanced equipment

A machine, tool or instrument designed with advanced technology and functionality to perform highly specific tasks with greater precision, efficiency and reliability.

High quality

Our products are *manufactured* to very high standards, using the finest materials and manufacturing processe.

Competitive price

We offer a higher-quality product or service at an equivalent price. As a result, we have a growing and loyal customer base.

Product Categories

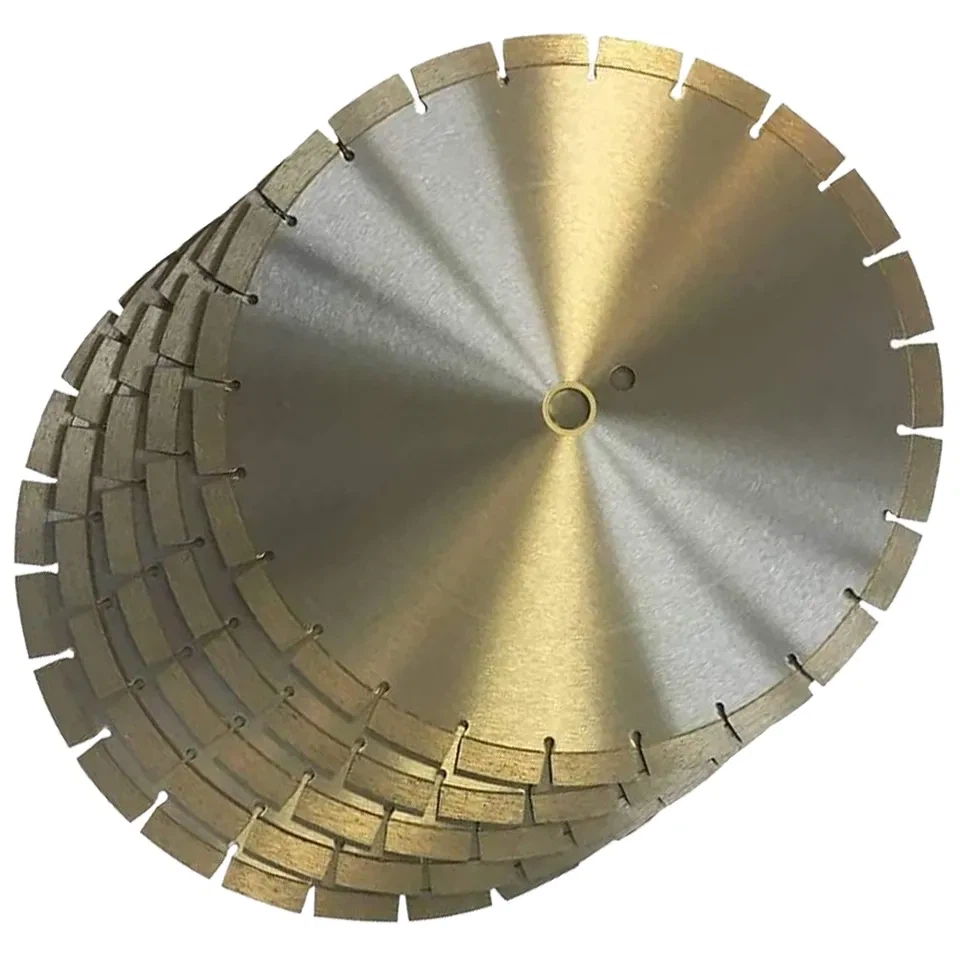

What is a Cutting Disc?

A cutting disc is a type of cutting tool that is used to cut or slice through various materials, such as metal, wood, plastics, and ceramics. It consists of a circular blade made of abrasive material, such as diamond, tungsten carbide, or corundum. Cutting discs come in various sizes and thicknesses and are used with different types of power tools, such as angle grinders, rotary tools, and chop saws. They are commonly used in industries such as metalworking, construction, and DIY home improvement projects.

Improved Performance

High-quality cutting discs are designed with advanced technology that allows for faster and more efficient cuts. They are made of premium materials that offer greater durability and can withstand the rigors of heavy use. This results in improved performance, increased productivity, and less downtime for maintenance or replacement.

Reduced Downtime

Downtime is a significant issue that impacts productivity and increases costs for businesses. Low-quality cutting discs wear out quickly, requiring frequent replacement and resulting in downtime for maintenance. On the other hand, high-quality cutting discs have greater durability and longevity, reducing the need for frequent replacement and resulting in less downtime for maintenance.

Greater Precision

Precision is an essential requirement in many industries. High-quality cutting discs are designed to provide precise cuts, allowing you to achieve the desired shape, size, and finish for your workpiece. The advanced technology and premium materials used in these discs ensure precise cuts every time, reducing waste and improving the quality of your work.

Safety

Safety is a critical concern when working with cutting discs. Low-quality discs can shatter or break during use, resulting in serious injuries. High-quality cutting discs are designed to ensure maximum safety by incorporating safety features such as reinforced cores and precision manufacturing. This reduces the risk of accidents and injuries, providing a safe work environment for operators.

Cost-Effective

High-quality cutting discs may be more expensive than their low-quality counterparts, but they offer long-term cost savings. They have greater durability, requiring less frequent replacement and resulting in reduced downtime for maintenance. Additionally, their advanced technology and precision design ensure greater efficiency and productivity, resulting in cost savings in the long run.

Types of Cutting Disc

Abrasive cutting discs:These are perhaps the most common type of cutting discs, and they use a blend of abrasive minerals, such as aluminum oxide, silicon carbide, or zirconia alumina, to grind and cut through materials like metal, masonry, and concrete.

Diamond cutting discs:As the name implies, these discs are tipped with diamond particles to cut through extremely hard materials like stone, glass, and ceramic.

Carbide cutting discs:Made from a mix of tungsten and carbon, carbide cutting discs are especially good at cutting through thick and dense materials like wood and plastics.

Ceramic cutting discs:These tough cutting discs are made from a blend of ceramic and aluminum oxide for use on materials like metal, stone, and masonry.

Flexible cutting discs:These are made from a flexible resin bond that allows them to bend and conform to the shape of the material being cut. They are often used for cutting curves and contours in metal and other materials.

Metal cutting discs:Designed specifically for cutting through metal, these discs are made from a blend of aluminum oxide and silicon carbide and often feature reinforced fiberglass mesh for added strength and durability.

Multifunctional cutting discs:These versatile cutting discs are designed to cut through a wide range of materials, including metals, ceramics, plastics, and wood. They often feature a combination of abrasive minerals to achieve this versatility.

Application of Cutting Disc

01.General fabrication

02.Pipe fabrication

03.Shipbuilding

04.Welding preparation

05.Railways

06.Construction

Material of Cutting Disc

Ceramic alumina: Ceramic alumina performs exceptionally well on steel, stainless steel, and other hard-to-cut metals, including inconel, high nickel alloy, titanium and armored steel. When used and maintained properly, it offers a superior lifespan and cut, and it tends to cut cooler than other grains, so it reduces heat discoloration.

Zirconia alumina: Zirconia alumina provides superior cutting for steel, structural steel, iron, and other metals, and it is ideal for rail cutting and other heavy-duty applications. It offers a fast cut and a long life and holds up under extreme pressure.

Aluminum oxide: Aluminum oxide is one of the most common abrasive grains. It provides a fast initial cut rate and consistent performance for steel and other metal.

Silicon carbide: Silicon carbide is an extremely hard grain that produces very sharp and fast cutting. However, it is also friable, meaning it is not as tough as other grains.

Components of Cutting Disc

Abrasive Material:The abrasive material is the main component of a cutting disc. It can be made of various materials such as aluminum oxide, silicon carbide, or diamond particles. The abrasive material determines the cutting properties, durability and product quality of the cutting disc.

Bonding Agent:The bonding agent holds the abrasive material together and attaches it to the cutting disc. It determines the strength and durability of the disc. Bonding agents can be made of different types of resins, such as phenolic, epoxy or polyimide, or ceramic materials.

Reinforcing Material:Reinforcing materials are added to improve the strength and durability of the disc. They can be made of various materials such as fiberglass, carbon fiber, or Kevlar.

Design Features:The design features of a cutting disc can affect its cutting performance. These features may include the size, thickness, shape, and edge of the disc. They can also include special features such as cooling holes or special coatings.

Diameter:The size of the cutting disc varies depending on the application. Common diameters include 4.5-inch, 5-inch, and 7-inch cutting discs.

Center Hole:The center hole is a crucial component of a cutting disc as it allows it to be mounted onto a cutting machine. The size and shape of the center hole must match the machine's spindle for safe and efficient operation.

Factors to Consider When Selecting Cutting Disc

Disc Type:There are different types of metal cutting discs available, such as abrasive discs, diamond discs, and carbide-tipped discs. Each type is designed for specific applications and materials, so choose the one that suits your cutting requirements.

Material Compatibility:Consider the type of metal you'll be cutting. Different discs are designed for cutting various metals, including steel, stainless steel, aluminum, or cast iron. Ensure that the disc you choose is compatible with the metal you're working with to achieve optimal results.

Disc Size:Metal cutting discs come in various sizes, typically ranging from 4 to 14 inches in diameter. Select a disc size that fits your cutting tool (e.g., angle grinder) and is appropriate for the size of the workpiece you're cutting.

Thickness:The thickness of the cutting disc affects its stability, durability, and cutting speed. Thicker discs are generally more robust and offer longer life but may sacrifice cutting speed. Thinner discs provide faster cutting but may wear out more quickly. Consider the balance between cutting speed and disc longevity based on your project requirements.

Speed Rating:Check the speed rating of the cutting disc and ensure it matches the maximum RPM (revolutions per minute) of your cutting tool. Exceeding the disc's speed rating can be dangerous and lead to accidents.

Quality and Brand:Choose reputable brands known for producing high-quality cutting discs. Quality discs tend to offer better performance, durability, and safety. Look for discs that meet industry standards and regulations to ensure their reliability.

Application:Consider the specific application and cutting task. For instance, if you need to make precise cuts or intricate designs, a finer or thinner disc might be suitable. For heavy-duty cutting or rough shaping, a more robust disc may be necessary.

Safety Features:Check if the cutting disc has any additional safety features, such as reinforced construction or special coatings that reduce heat buildup or minimize sparks. These features can enhance safety during cutting operations.

Cost:While it's essential to consider your budget, prioritize quality and suitability over price alone. Investing in a reliable and appropriate cutting disc can improve efficiency, produce better results, and enhance safety.

Factors to Consider When Selecting Cutting Disc

Disc Type:There are different types of metal cutting discs available, such as abrasive discs, diamond discs, and carbide-tipped discs. Each type is designed for specific applications and materials, so choose the one that suits your cutting requirements.

Material Compatibility:Consider the type of metal you'll be cutting. Different discs are designed for cutting various metals, including steel, stainless steel, aluminum, or cast iron. Ensure that the disc you choose is compatible with the metal you're working with to achieve optimal results.

Disc Size:Metal cutting discs come in various sizes, typically ranging from 4 to 14 inches in diameter. Select a disc size that fits your cutting tool (e.g., angle grinder) and is appropriate for the size of the workpiece you're cutting.

Thickness:The thickness of the cutting disc affects its stability, durability, and cutting speed. Thicker discs are generally more robust and offer longer life but may sacrifice cutting speed. Thinner discs provide faster cutting but may wear out more quickly. Consider the balance between cutting speed and disc longevity based on your project requirements.

Speed Rating:Check the speed rating of the cutting disc and ensure it matches the maximum RPM (revolutions per minute) of your cutting tool. Exceeding the disc's speed rating can be dangerous and lead to accidents.

Quality and Brand:Choose reputable brands known for producing high-quality cutting discs. Quality discs tend to offer better performance, durability, and safety. Look for discs that meet industry standards and regulations to ensure their reliability.

Application:Consider the specific application and cutting task. For instance, if you need to make precise cuts or intricate designs, a finer or thinner disc might be suitable. For heavy-duty cutting or rough shaping, a more robust disc may be necessary.

Safety Features:Check if the cutting disc has any additional safety features, such as reinforced construction or special coatings that reduce heat buildup or minimize sparks. These features can enhance safety during cutting operations.

Cost:While it's essential to consider your budget, prioritize quality and suitability over price alone. Investing in a reliable and appropriate cutting disc can improve efficiency, produce better results, and enhance safety.

What You Should Know When Use Cutting Disc

Choose the right disc for the job:Make sure you choose the right cutting disc for the material you are cutting. The wrong type of disc may not be able to cut through the material or may even break.

Safety first:Always wear protective gear such as safety glasses, gloves, long sleeves, and pants, and a dust mask to protect yourself from dust and debris.

Inspect the disc:Before use, inspect the cutting disc for any cracks or damage. If you notice any damage, do not use the disc.

Use the correct size disc:Make sure you use the correct size disc for the tool you are using. Using the wrong size disc could cause the disc to break or fly off the tool.

Use a compatible tool:Only use cutting discs that are compatible with the tool you are using.

Keep the workpiece secured:Make sure the workpiece is securely clamped or held in place to prevent movement during cutting.

Follow proper cutting technique:Use a steady, even pressure and avoid applying too much force or pushing too hard.

Let the disc cool:It is important to let the disc cool down before storing it or attempting to remove it from the tool. A hot disc can be dangerous.

Dispose of the disc properly:Once the disc has worn out, dispose of it properly. Do not simply throw it away in the trash as it can be dangerous. Check with your local waste disposal company for instructions on how to dispose of cutting discs.

How to Maintain Cutting Disc

Check the Cutting Disc for Damage

Before using a cutting disc, inspect it for any visible damage or cracks. A damaged disc increases the risk of accidents.

Proper Storage

Store the cutting discs in a dry and protected area away from other tools and materials. Avoid damp or humid areas that can cause rust.

Cleaning

After each use, clean the cutting disc with a brush and wipe it with a cloth to remove any debris or dust. This will prevent the accumulation of dirt and prolong the life of the disc.

Sharpening

If the cutting disc becomes dull, it is time to replace it. Sharpening a cutting disc is not advisable as it can compromise its structural integrity and lead to accidents.

Proper Handling

Follow the manufacturer's recommendations for the use and handling of the cutting disc. Always use the appropriate safety equipment such as gloves, goggles and a face shield to protect yourself.

Proper Mounting

Ensure that the cutting disc is mounted properly and securely onto the tool. An improperly mounted disc can cause vibrations and damage to the tool.

Properly align the cutting disc

If the cutting disc is not properly aligned, it can cause damage to the disc and reduce its effectiveness.

Check the cutting disc regularly

Regularly inspecting the cutting disc for signs of wear and damage can help prolong its lifespan and ensure it operates safely.

Certifications

Our Factory

Our company has been committed to the international development in stone industry since its establishment 2016.All our abrasive products are made with quality materials and exceed ANSI and EU European Standards.We trust in delivering high-quality products to the end-user. Customer satisfaction is the lifeline of our quality.

Frequently Asked Questions Cutting Disc

As one of the leading cutting disc manufacturers and suppliers in China, we warmly welcome you to wholesale discount cutting disc made in China here from our factory. All our products are with high quality and competitive price.

angle grinder blade for cutting metal, metal blade for angle grinder, 230mm tile blade